SND-M10 Sintetis Micron Diamond Powder Polishing Abrasive Kanggo Tujuan Umum

SND-M10 Sintetis Micron Diamond Powder Polishing Abrasive Kanggo Tujuan Umum

1. Micron Diamond Powder Pambuka

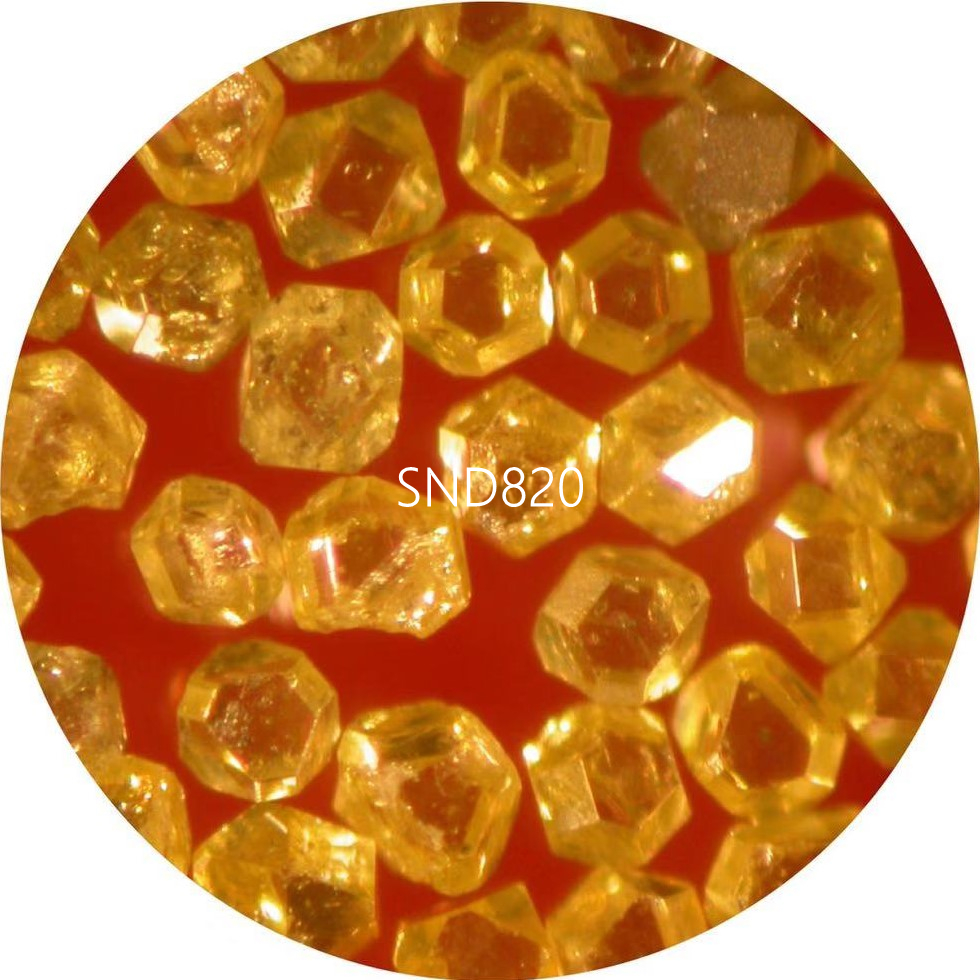

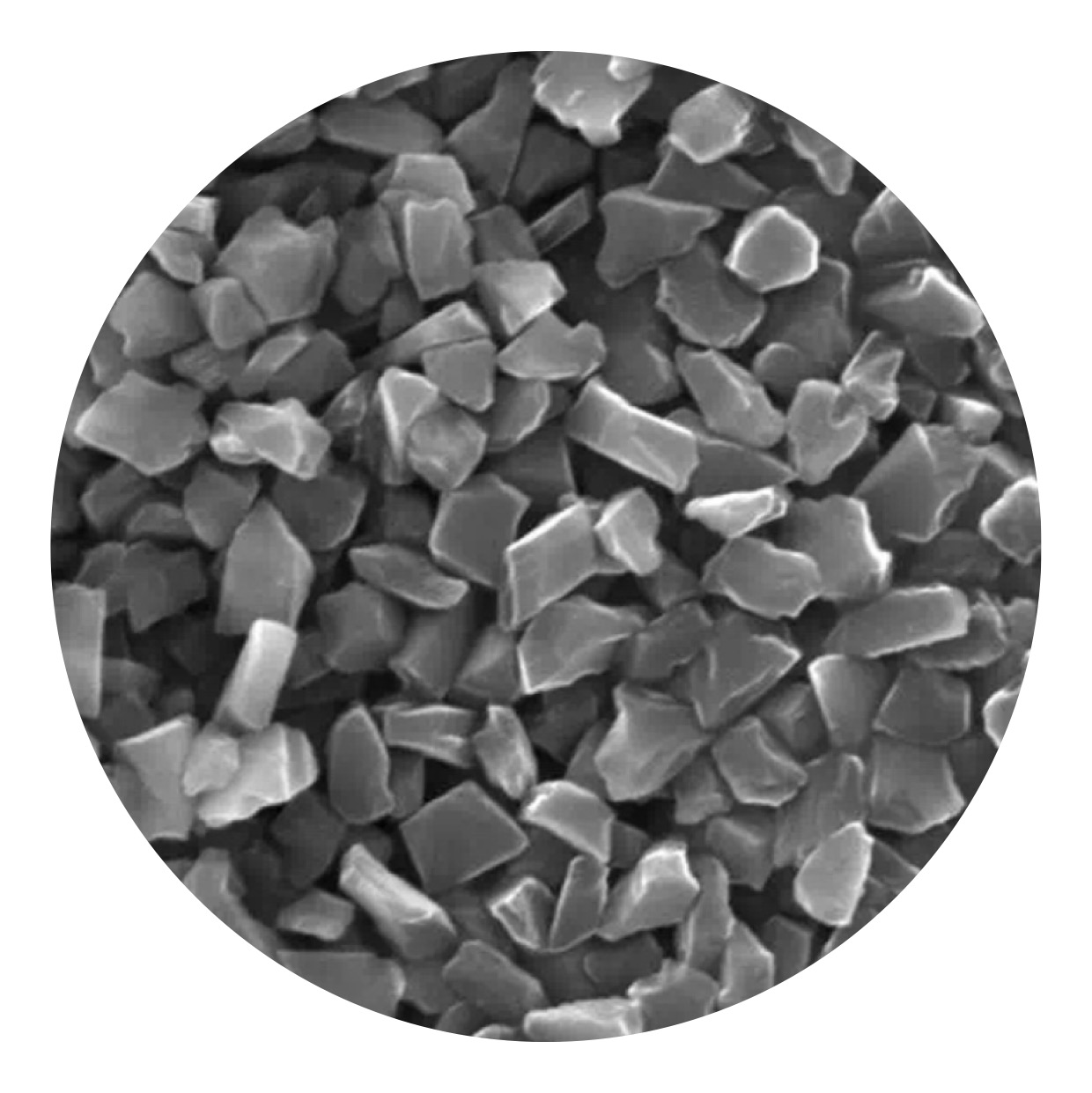

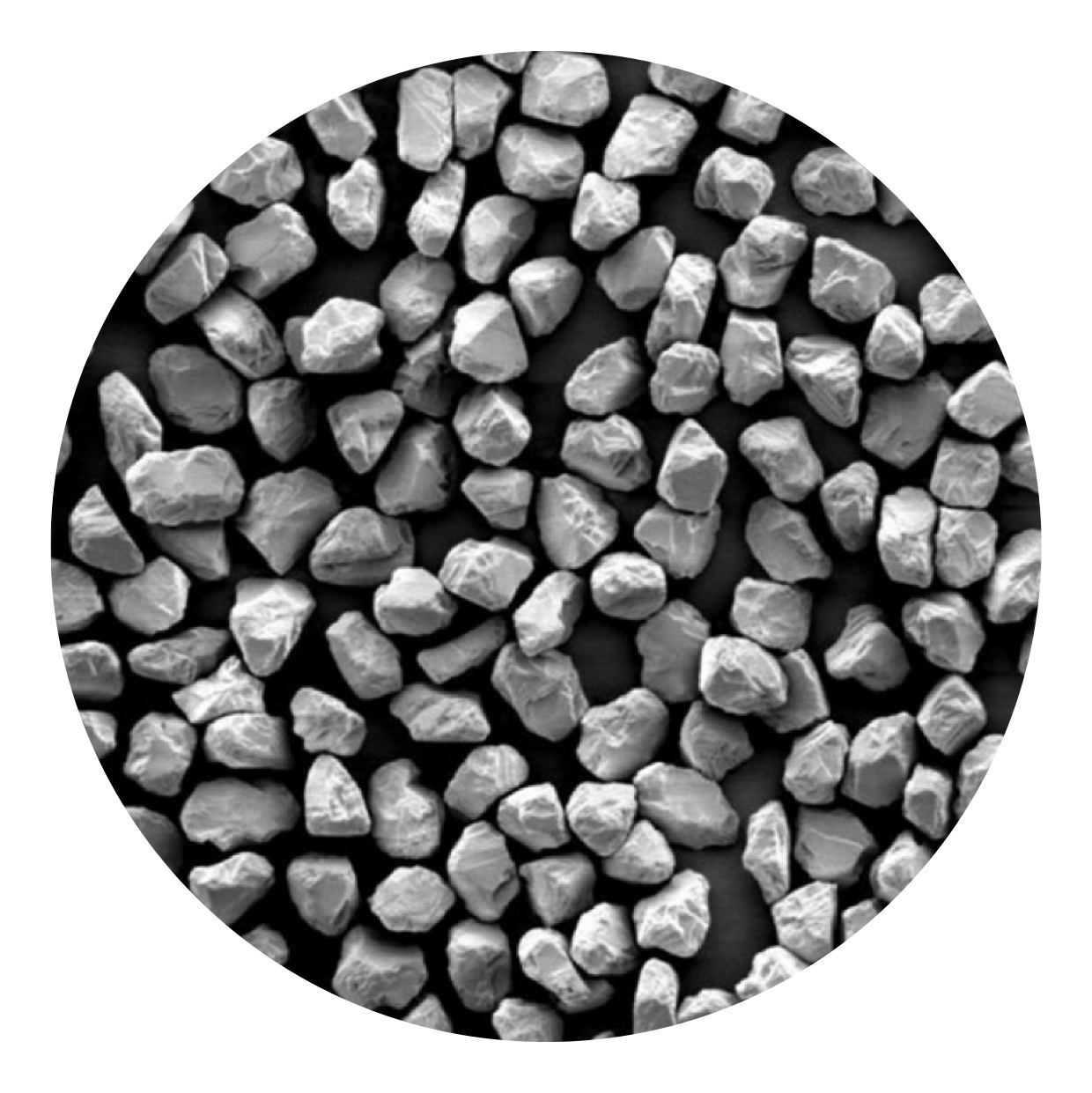

SND-M10 minangka bubuk berlian mikron umum kanthi bentuk kristal sing ora duwe aturan bakurelatif klempakandistribusi ukuran partikel,isi impurity kurang.dhuwurefisiensi.Bisa digunakake ingresin,

vitrified, ikatan logamlan produk electroplated.

2. Spesifikasi Micron Diamond Powder

|  |  |

| SND-M05 0-0.125~40-60 | SND-M10 0-0.125~40-60 | SND-M15 0-0.125~40-60 |

| Bentuk kristal sing ora teratur, kandungan dan partikel pengotor distribusi ukuran, bisa digunakake ing resin lan ikatan vitrified. Cocog kanggo efisiensi dhuwur mecah lan polishing aplikasi, kayata watu, kothak, Jade & gem, etc. | wangun kristal ora duwe aturan baku karo relatif klempakan distribusi ukuran partikel, isi impurity kurang.dhuwur efisiensi.Bisa digunakake ing resin, vitrified, ikatan logam lan produk electroplated. | Blok gandum, relatif ukuran partikel konsentrat distribusi, impurities cilik, hidrofilik sing nguntungake kinerja.Cocog kanggo lapping syarat dhuwur, polishing, bisa digunakake kanggo PCD berlian kualitas dhuwur tempel lan slurry lan liyane produk berlian kualitas dhuwur. |

3. Micron Diamond kasedhiya Grit Size

| Standar Internasional | China Standard | Ukuran Mesh | Aplikasi |

| 0-0.1 | W0.1 | 100000 | Super Mirror Polishing |

| 0.0.25 | W0.25 | 60000 | Super Mirror Polishing |

| 0-0.5 | W0.5 | 30000 | Pangilon Polishing |

| 0-1 | W1 | 15000 | Pangilon Polishing |

| 0-2 | W1.5- | 13000 | Polishing apik |

| 1-2 | W1.5 | 12000 | Polishing apik |

| 1-3 | W2.5 | 10000 | Polishing apik |

| 2-4 | W3.5 | 6500 | Polishing apik |

| 2-5 | W4 | 5000 | Polishing apik |

| 3-6 | W5 | 4000 | Polishing apik |

| 4-6 | W6 | 3500 | Polishing apik |

| 4-8 | W7 | 3000 | Polishing Normal |

| 4-9 | W10 | 2500 | Polishing Normal |

| 5-10 | W10 | 2000 | Polishing Normal |

| 6-12 | W10 | 1800 | Polishing Normal |

| 8-12 | W12 | 1600 | Polishing Normal |

| 7-14 | W14 | 1500 | Polishing Normal |

| 8-16 | W14 | 1300 | Polishing Normal |

| 10-20 | W20- | 1200 | Polishing Normal |

| 12-22 | W20 | 1000 | Polishing Normal |

| 15-25 | W20+ | 800 | Polishing Normal |

| 20-30 | W28 | 700 | Polishing Normal |

| 22-36 | W28+ | 600 | Penggilingan Kasar |

| 20-40 | W40- | 500 | Penggilingan Kasar |

| 30-40 | W40 | 450 | Penggilingan Kasar |

| 35-45 | W40+ | 400 | Penggilingan Kasar |

| 36-54 | W50 | 350 | Penggilingan Kasar |

| D46 | 325/400 | 320 | Penggilingan Kasar |

| D54 | 270/325 | 270 | Penggilingan Kasar |

| D64 | 230/270 | 230 | Penggilingan Kasar |

| D76 | 200/230 | 200 | Penggilingan Kasar |

4. Ukuran Grit Coarse liyane

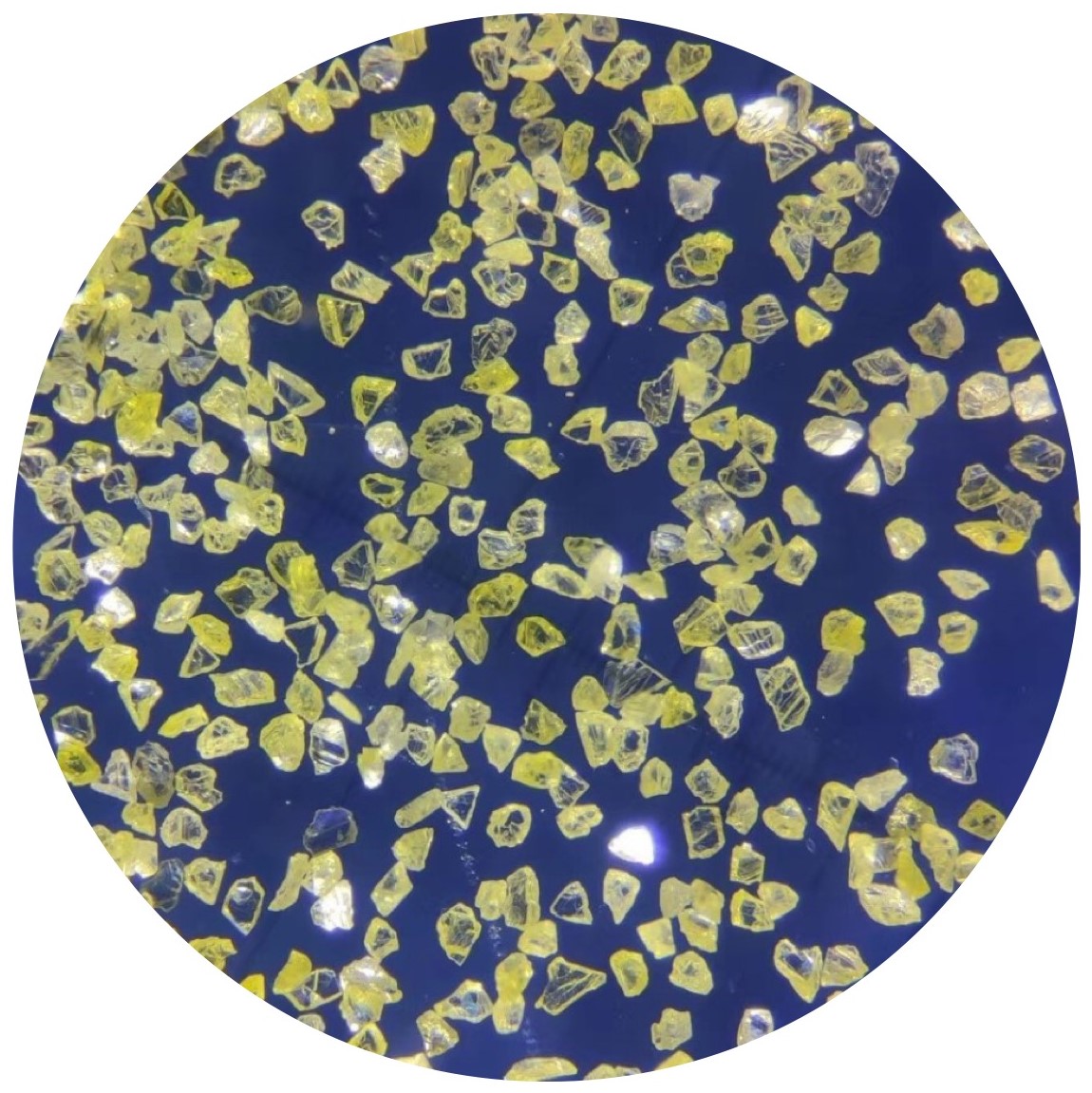

| 50/60-325/400 | Werna ijo cahya, wangun ora duwe aturan baku karo kateguhan ngisor.Jembar digunakake kanggo ngolah watu, beton, keramik, lsp. | |

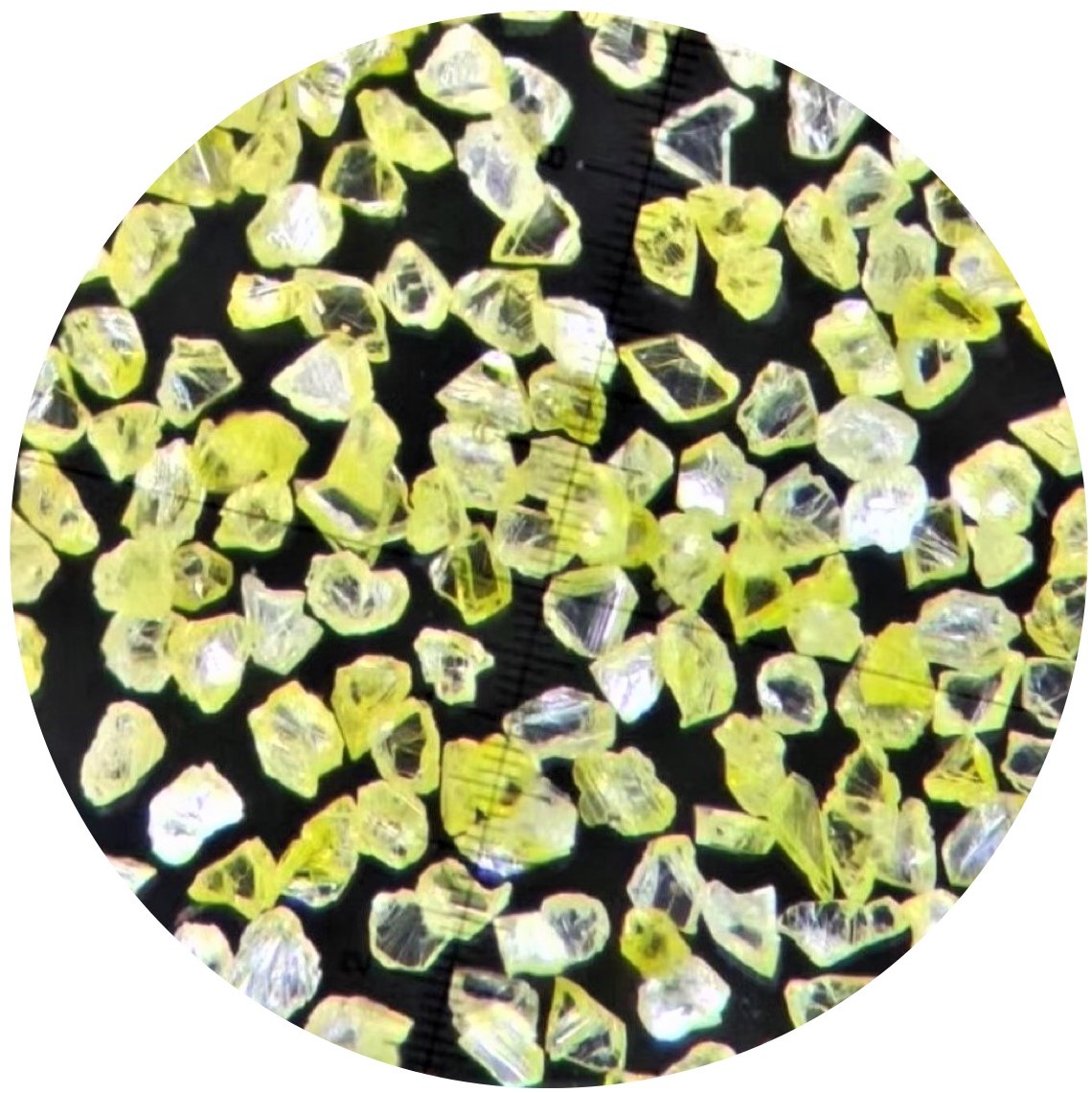

| 30/35-325/400 | Werna kuning, wangun ora duwe aturan baku karo atose standar, Applied ing ikatan keramik, ikatan resin lan kabeh jinis elektroplating produk, kanggo ngolah watu, paduan keras, bahan magnetik, berlian alami, permata. | |

| 30/35-325/400 | Werna kuning, kekerasan dhuwur lan kateguhan.Applied ing Keramik jaminan, jaminan resin lan kabeh jinis produk electroplating, bisa digunakake kanggo pangolahan tugas abot ing karbida, kaca, keramik, watu lan bahan non-logam liyane. |