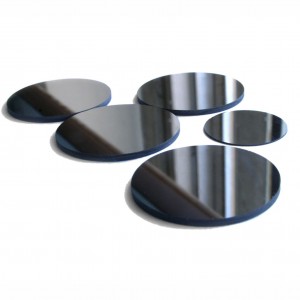

Polycrystalline Cubic Boron Nitride (PCBN) kanggo Aplikasi Mesin

komposit PCBN diprodhuksi dening sintering wêdakakêna CBN micron karo macem-macem Keramik, supaya minangka kanggo gawé bahan perkakas arang banget hard lan thermally stabil.CBN minangka bahan paling angel nomer loro sing dikenal sawise berlian sintetik, nanging nduweni sifat tahan termal lan kimia sing dhuwur.Iki utamané dipigunakaké ing nglereni lan Processing saka atose dhuwur utawa angel kanggo proses bahan kalebu baja hardened, werna abu-abu lan kekuatan dhuwur cast wesi, baja kacepetan dhuwur, cast wesi quench alloy, bahan logam sintering, etc.

| Kode # | Dhiameter (mm) | Lapisan berlian (mm) | Dhuwur (mm) | Rasio abrasif | Fitur | Aplikasi |

| HC1303 | 13.5 | 0.8-1.0 | 3.2 | > 10000 |

Lapisan CBN lan substrat Wc-co Isi CBN Dhuwur 2. resistance nyandhang dhuwur 3. Kekuwatan pecah sing apik 4. stabilitas kimia apik | 1. Dimensi sing tepat2.Wesi tuang abu-abu3.Powered Metal4.Tahan panas 5. Quench alloy 6. Alat baja & baja mati |

| HCF1304 | 13.5 | 0.8-1.0 | 4.5 | |||

| HC3201 | 32.0 | 0.8-1.0 | 1.6 | |||

| HC3202 | 32.0 | 0.8-1.0 | 2.4 | |||

| HC3203 | 32.0 | 0.8-1.0 | 3.2 | |||

| LC1303 | 13.5 | 0.8-1.0 | 3.2 | > 3000-4000 |

Lapisan CBN lan substrat Wc-co 2. Isi CBN sing relatif kurang 3. Rasio nyandhang dhuwur 4. Kekuwatan anti pecah sing apik |

bagean metallurgy |

| LC1304 | 13.5 | 0.8-1.0 | 4.0 | |||

| LC3201 | 32.0 | 0.8-1.0 | 1.6 | |||

| LC3202 | 32.0 | 0.8-1.0 | 2.4 | |||

| LC3203 | 32.0 | 0.6-0.8 | 3.2 | |||

| HB0903 | 9.55 | 3.18 | 3.18 | > 5000 |

|

|

| HB1204 | 12.7 | 4.76 | 4.76 | |||

| HB1608 | 15.85 | 8.0 | 8.0 | |||

| HB2008 | 20.0 | 8.0 | 8.0 |